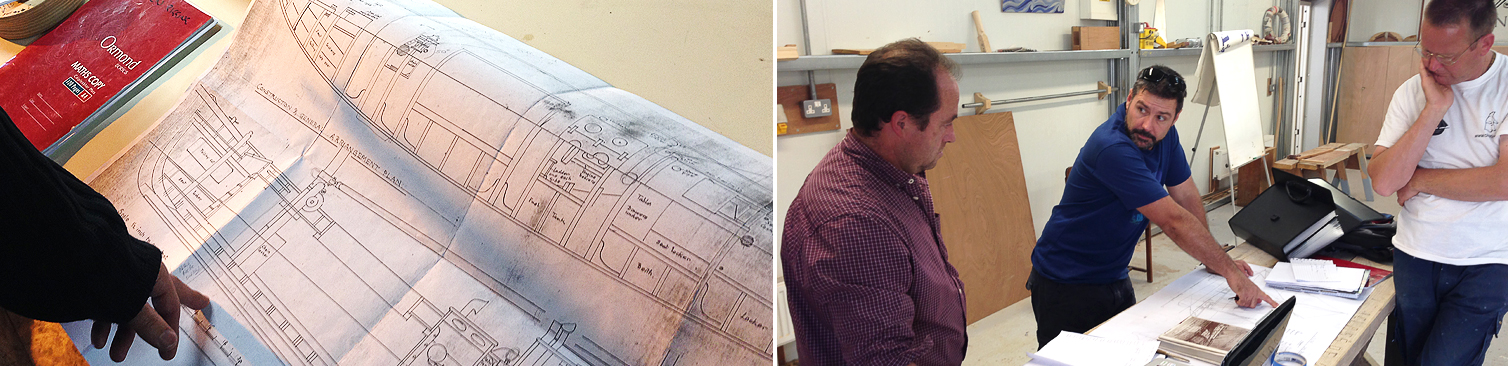

The task is immense, but the team in Ireland and across the globe are proving ready for the challenge.

The sourcing of timber and skills, the logistics of bringing everything together from a wide base stretching the length and breadth of Munster and beyond have depended on a little planning and a deep unspoken unanimity on what needs to be done.Much of the heavy lifting, of frames, planking, deadwoods & backbone, knees, floors, shelves and stringers, deck beams, and carlins, has been done or is being done in Hegarty’s Boatyard, Oldcourt.

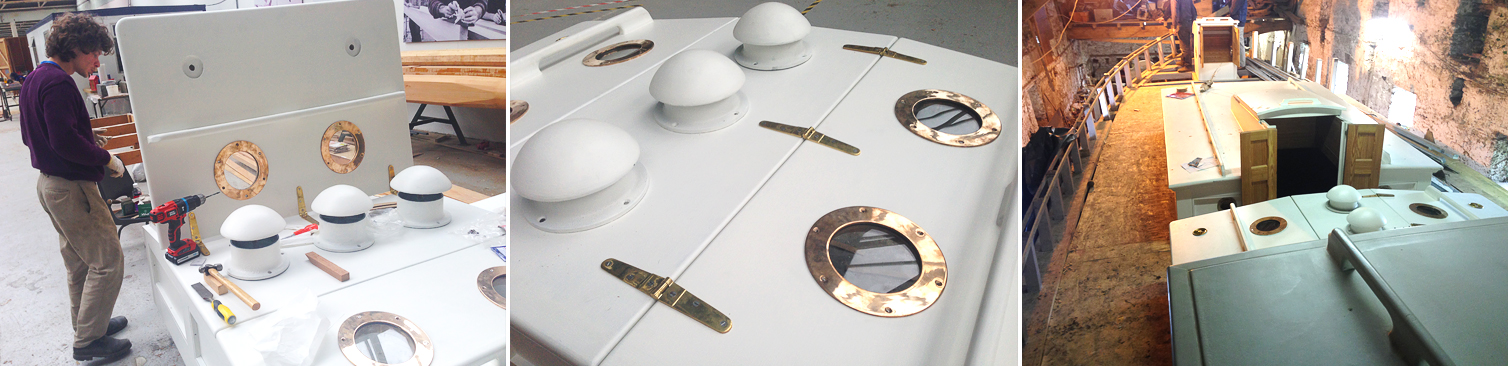

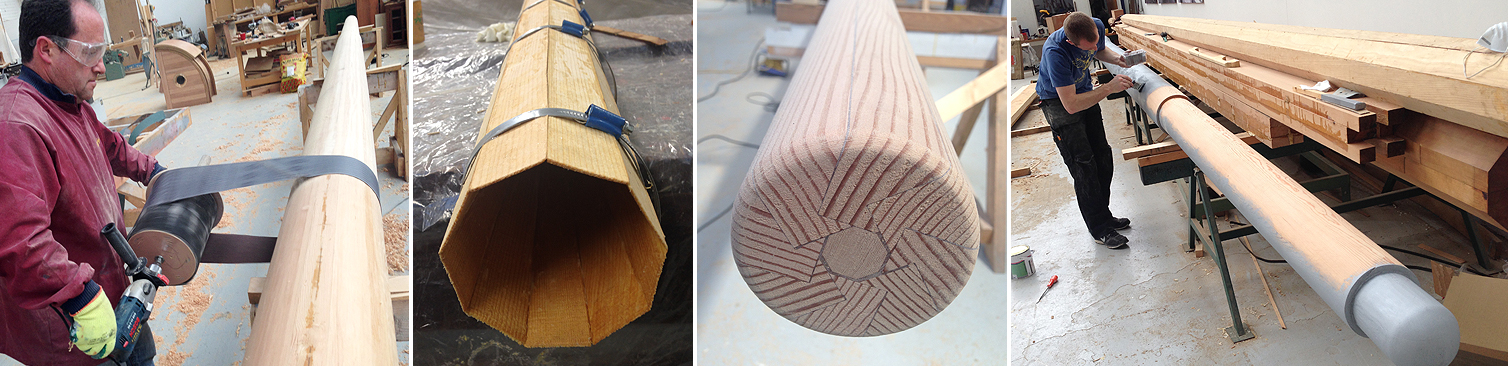

The generally lighter work of preparing sole, bulkheads, deck‐houses fixed furniture, fixtures & fittings, deck fittings, machinery, systems, tanks, spar making and rigging is being done in our school in Limerick, in the hope, every time we send a completed deck house to Hegarty’s yard, that our measurements were correct. It has proved in fact a workable process.

Project coordination and sequencing of craftsmen many miles apart is made possible by a sense of good and common purpose.

With the coming of the Ilen to Limerick in July 2016, the focus of journeys will change, with the journeymen shipwrights of the South West and other distant parts of the Earth coming to Thomond.

And although the ship demands the highest standards from these consummate marine craftsmen, she also benefits from the work of volunteers who happily give their labour to this community endeavour.

Work to be done in Limerick includes:

– Cable trunking, major cables, switchboard(s), battery bank(s), main consumers.

– Water / waste tank(s), main pipe runs, location of pump(s) etc.

– Fuel tanks & associated pipework.

– Completion of sole & bulkheads, doors, etc., and major fixed furniture

– Fit out of galley & head(s) areas, including equipment.

– Interior & exterior painting / varnish etc.

– Fabrication / purchase & mounting spar fittings, spar varnishing.

– Completion of deck (e.g. deck fittings, vents & cowls, cap rail)

– Purchase of running rigging, blocks, sails, dead-eyes, completion of standing rigging.

– Second fit, connection & commissioning all electrical systems.

– Completion & testing of fresh, bilge, sea & grey / black water systems.

– Second fit to interior including movable furniture, grab handles.

– Internal chandlery (handles, catches, lights etc), final paint work.

– Dress & step masts & spars, complete running & standing rigging, bend sails.

– Purchase of gear & inventory (tools, tender, safety equipment, first aid kit etc).

– Purchase & fitting of navigation & communications (VHF etc) equipment.

– Relaunch, sea-trials, insurance, Dept of Transport fees etc.